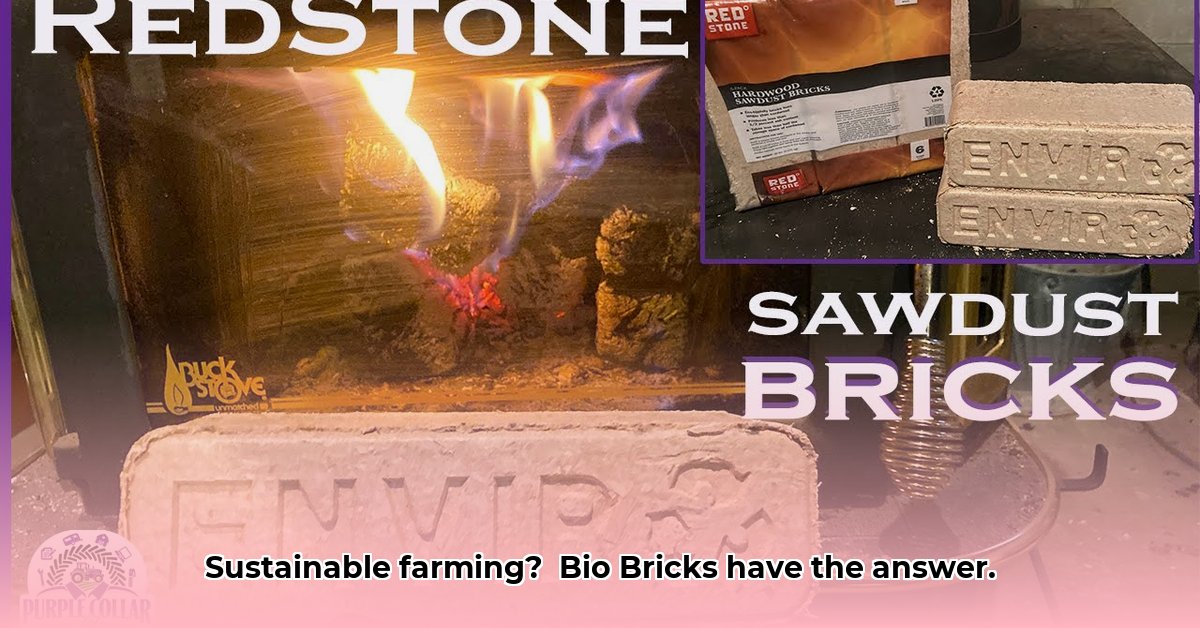

Tired of soaring fuel costs and the environmental impact of traditional diesel? Imagine powering your tractors with a fuel source you can grow or source locally – a fuel that's both budget-friendly and environmentally conscious. This guide explores the potential of biomass fuels, specifically "bio-bricks" (compressed biomass fuel), as a sustainable alternative. We'll guide you through the process, from assessment to implementation, emphasizing practical steps and cost-effective strategies. Let's build a more sustainable and profitable future for your farm! For more on sustainable farming practices, check out these helpful resources.

Understanding Biomass Fuels: Beyond the Bio-Brick

Biomass fuels harness the energy stored in plants. This isn't some futuristic technology; it's about utilizing readily available resources like wood pellets, agricultural residues (think leftover corn stalks and wheat straw), and even specially cultivated energy crops. Each type offers varying energy density (how much energy is packed into a given amount), influencing its suitability for your needs. Sustainable sourcing is key: We're focused on responsible resource utilization, minimizing environmental impact.

Is Biofuel Right for Your Farm? A Practical Assessment

Before investing, consider whether your farm is truly suited for this transition. This isn't a one-size-fits-all solution; it requires careful planning.

A Quick Checklist:

- Biomass Availability: Do you have sufficient local biomass resources (agricultural waste, fast-growing energy crops)? Transportation costs will significantly impact feasibility. Are readily available resources sufficient for your demands?

- Farm Size and Equipment: Do you have adequate storage space for biomass fuel? Is your current tractor equipment compatible, or will upgrades be necessary (a significant cost factor)?

- Budget: Factor in the initial investment (system cost, installation) and ongoing maintenance expenses. What's your realistic budget for this conversion?

- Technical Expertise: Do you possess, or can you access, the necessary skills for system operation and maintenance? Will you need to hire specialized technicians?

This preliminary assessment helps determine if bio-bricks are a viable option for your farm.

Selecting the Right Biofuel System: Making the Right Choice

Choosing a combustion system is crucial for efficiency and cost-effectiveness. Consider these factors:

- System Size: Match the system’s capacity to your tractor's fuel consumption. Too small, and it won't suffice; too large, and it’s an unnecessary expense.

- Efficiency: Higher efficiency means less wasted energy and lower operating costs. Look for systems with high energy conversion rates.

- Fuel Compatibility: Can the system handle diverse biomass fuels? Flexibility is beneficial to adapt to changing resource availability.

- Budget: Set a realistic budget and compare options from multiple suppliers.

- Space Requirements: Ensure your farm has enough space for the system and fuel storage.

- Technical Support: Consider the level of ongoing technical support required and its associated costs. Do you have access to competent technicians?

Sourcing and Handling Biofuel: From Field to Combustion

Sustainable sourcing is non-negotiable. The environmental benefits are lost if harvesting practices aren't responsible.

- Sustainable Harvesting Practices: Verify that your supplier employs environmentally sound methods. Look for certifications or inquire directly about their harvesting techniques.

- Proper Storage: Store bio-bricks in a dry, ventilated space away from ignition sources. Adequate storage prevents spoilage and fire hazards.

- Moisture Content: High moisture significantly reduces fuel efficiency. Ensure your fuel is properly dried before use.

- Transportation: Minimize transportation costs by sourcing locally whenever possible.

Installing and Operating Your System: A Phased Approach

This is best left to qualified professionals. Improper installation can lead to safety hazards and reduced efficiency.

- Professional Installation: Hire experienced technicians to ensure safe and optimal installation.

- Start-up Procedure: Follow the manufacturer's instructions carefully to ensure smooth and safe operation.

- Regular Maintenance: Implement a proactive maintenance schedule to maximize system lifespan and efficiency.

- Basic Troubleshooting: Learn basic troubleshooting to address minor issues independently, reducing downtime and service costs.

The Economics of Biofuel: Cost-Benefit Analysis

While there's an upfront investment, the potential long-term savings are considerable.

Potential Cost Savings:

- Reduced reliance on volatile fossil fuel prices.

- Possible government incentives and subsidies (check local and national programs).

Factors Influencing ROI:

- Initial system cost.

- Ongoing fuel costs (compare suppliers).

- Regular maintenance expenses.

- System efficiency.

A thorough cost-benefit analysis is crucial before committing to this transition.

Environmental Impact: A Sustainable Choice

Biofuels offer a substantially lower carbon footprint than fossil fuels, contributing to reduced greenhouse gas emissions and decreased reliance on finite resources. However, unsustainable harvesting practices negate these benefits; responsible sourcing is equally important.

Legal and Regulatory Compliance: Navigating the Rules

Familiarize yourself with local environmental, emission, and waste disposal regulations. Obtain all necessary permits before beginning operation. Failure to comply can lead to significant penalties.

Conclusion: Embracing Sustainable Solutions

Though initially challenging, switching to biomass fuels offers considerable long-term advantages. By carefully assessing your farm's suitability, choosing the right system, and prioritizing responsible sourcing, you can achieve significant operational and environmental gains. Start small, learn incrementally, and reap the rewards of a more sustainable and potentially more profitable farm.